Quality and Environment

Offering a high quality product has always been our primary target. To obtain and guarantee this result we operate on the following factors:

- Suppliers: the components we use for commercial parts (bearings, gaskets, ring nuts, etc.) are supplied only by leading companies in the sector. The supply chain is monitored and certified on a regular basis.

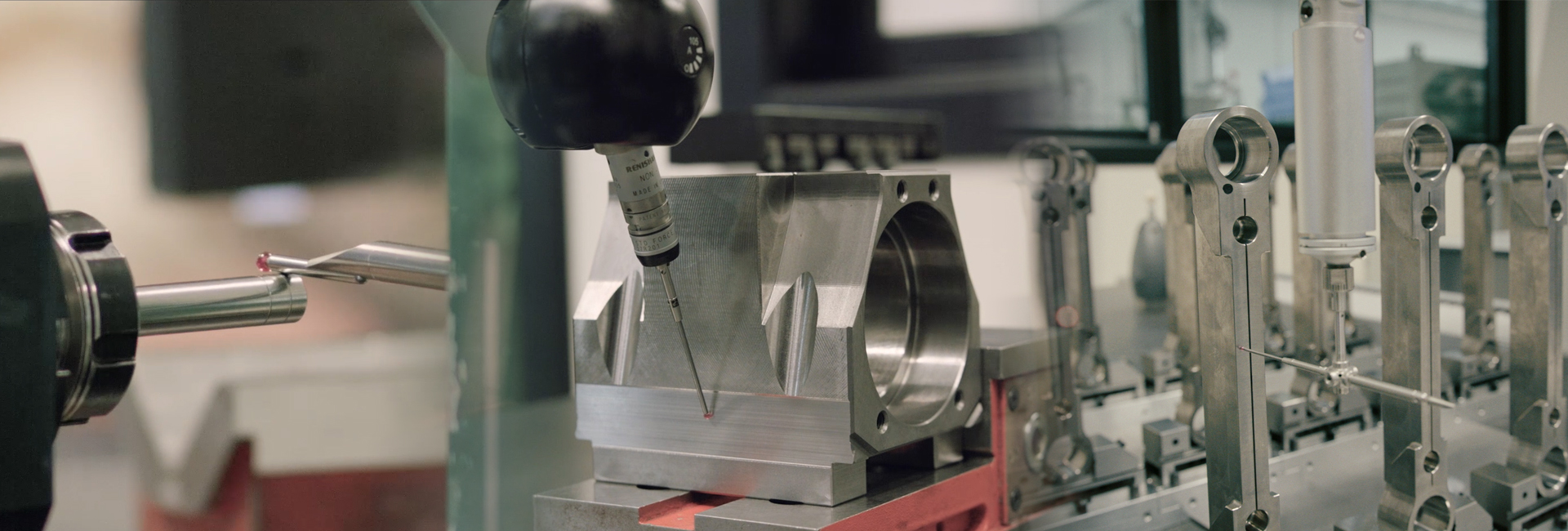

- Production: we adopt a precise and rigorous process control with controls on the machine in all the significant stages of processing.

- Testing: before shipping, we test 100% of our production.

- Traceability: we mark each of our products, indicating the serial number and the date of shipment with the most important goal of facilitating any post-installation activity.

Our testing department is equipped with three-dimensional measuring machines, optical reading profile detection tools and tools for measuring geometry and shapes. The quality of our production, together with the certainty of the technical solutions used, allow us to offer a two-year warranty period on our range of motorized tool holders starting from the shipping date, which is marked on each individual product.

Our testing department is equipped with three-dimensional measuring machines, optical reading profile detection tools and tools for measuring geometry and shapes. The quality of our production, together with the certainty of the technical solutions used, allow us to offer a two-year warranty period on our range of motorized tool holders starting from the shipping date, which is marked on each individual product.

Our certifications

On 24 February 2016 we were among the first companies in Italy to obtain certification according to the new 2015 editions of the UNI EN ISO 9001 standards relating to the company quality management system and UNI EN ISO 14001 relating to the environmental management system.

From 21 December 2020 we have also obtained the AS9100D / EN9100: 2018 and ISO 9001: 2015 certification for precision machining for the aerospace and industrial market.

The high quality level of our products is widely recognized in the world:

You can download our Quality certificates and our Quality and Environment Policy in the Download area

, then

, then to install our app

to install our app