Toolholders for CNC Lathes

We design and manufacture static and driven tool holders for turning machines to respond in an innovative and effective way to your precision machining needs. Our range includes models for all the most prestigious brands of lathes, both slant bed with disc and polygonal turret, and for flat bed and swiss type lathes.

Our catalog includes over 12,000 items that allow us to satisfy any processing requirement. However, if the model of your interest is not yet part of our product range, we also create customized projects based on the needs of our customers.

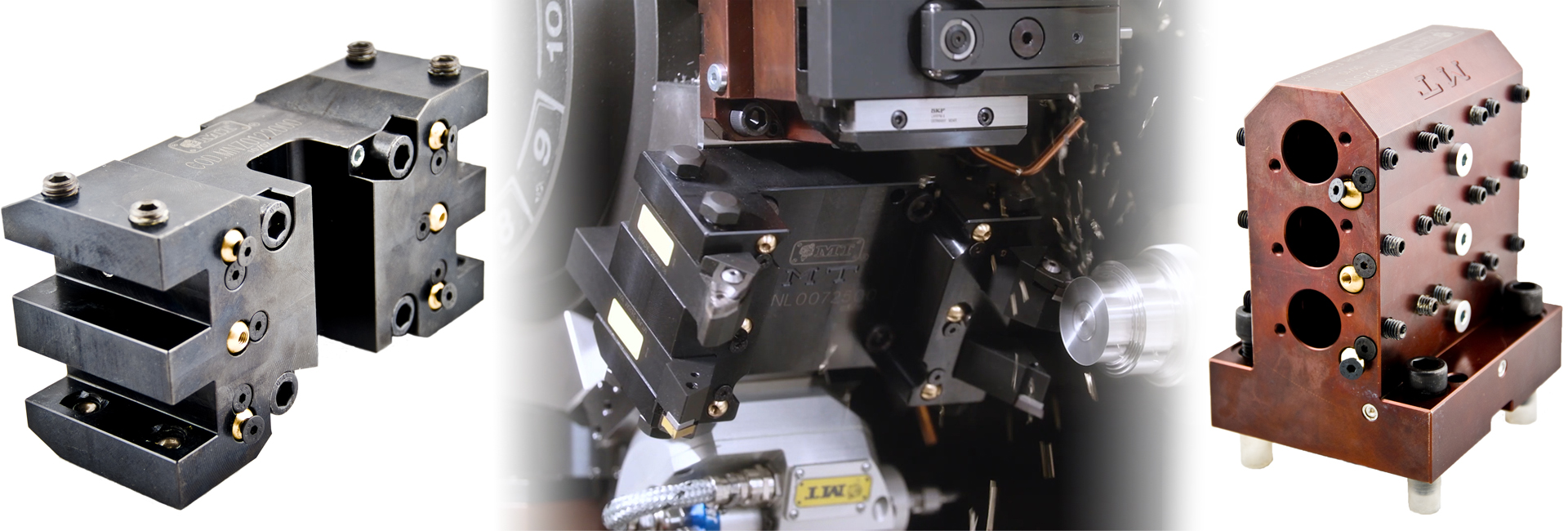

Static tool holders:

Our static tool holders are designed with the highest precision and rigidity in both turning and boring operations.

We produce multiple turning tool holders, suitable for the simultaneous assembly of 2 or 4 tools, even with internal cooling on the tool.

We also offer multiple boring bar holders, suitable for the assembly of up to 4 + 4 boring bars at the same time for machining on the main and counter spindle, deformation bar holders, blade holders and multiple static holders. Our boring bar holders are equipped with a mechanism that allows the on / off selection of the internal cooling circuit.

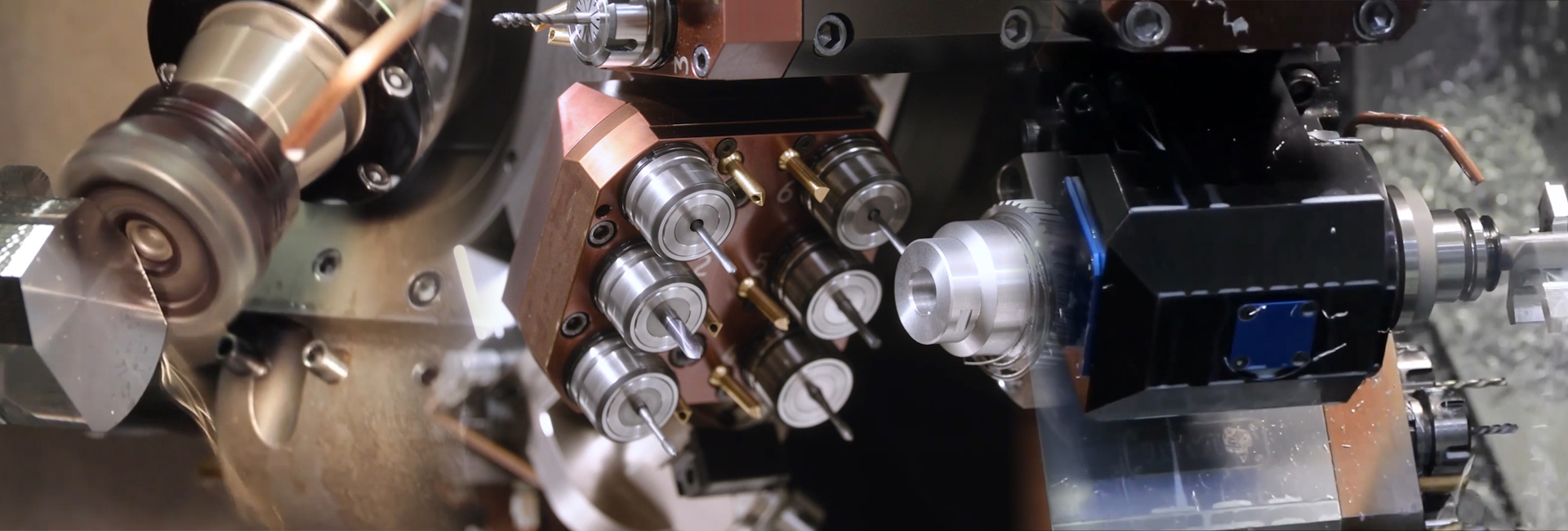

Driven tool holders:

Our driven tool holders are designed using state-of-the-art technical solutions, combining precision and high load capacity to allow you to make full use of the features made available by the machine.

Some of the advantages offered by our solutions:

- Increase the machining parameters, thanks to the oversized internal components.

- High precision bearings for high speed and load capacity

- Reduced noise and heating thanks to the convex profile gears and the run-in and ground bevel gears.

- Maximum lifetime, thanks to the ceramic coating treatment on the output shafts.

- Possibility of internal coolant up to 70 bar with mechanical seals.

- Flexibility, thanks to ER / ERA collet, mill-holder, Weldon and MT-Capto and MTSK quick change systems

- Reduction of set-up times, thanks to the use of multiple driven toolholders and quick tool change systems.

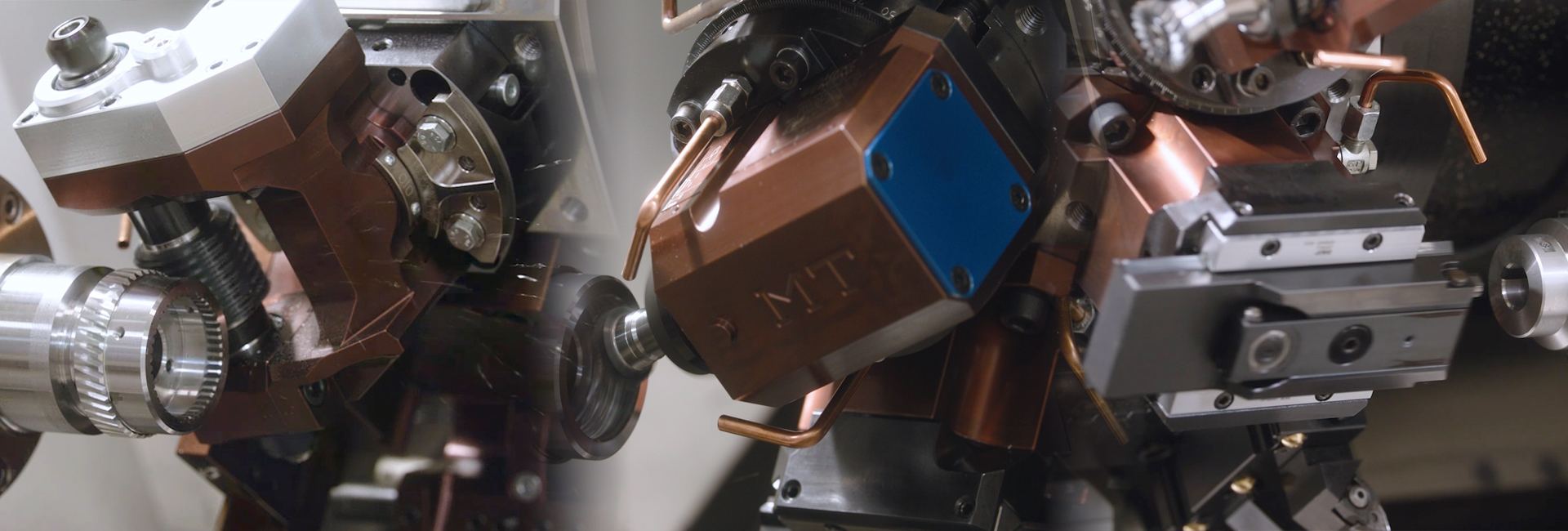

Advanced machining:

MT is a world leader in advanced lathe machining. In addition to standard tool holders, in our catalog you can find solutions for machining:

- Angles drilling and threading: adjustable driven toolholder

- External gears: driven gear hobbing module

- Internal gears: lathe power skiving module

- Internal profiles: 91 ° broaching module

- Keyways: slotting module

- Broaching of internal and external gears, keyways: driven broaching toolholder

- Supporting of long workpiece: steady rest module

- High speed grinding, drilling and threading: X11 Powered Electrospindle

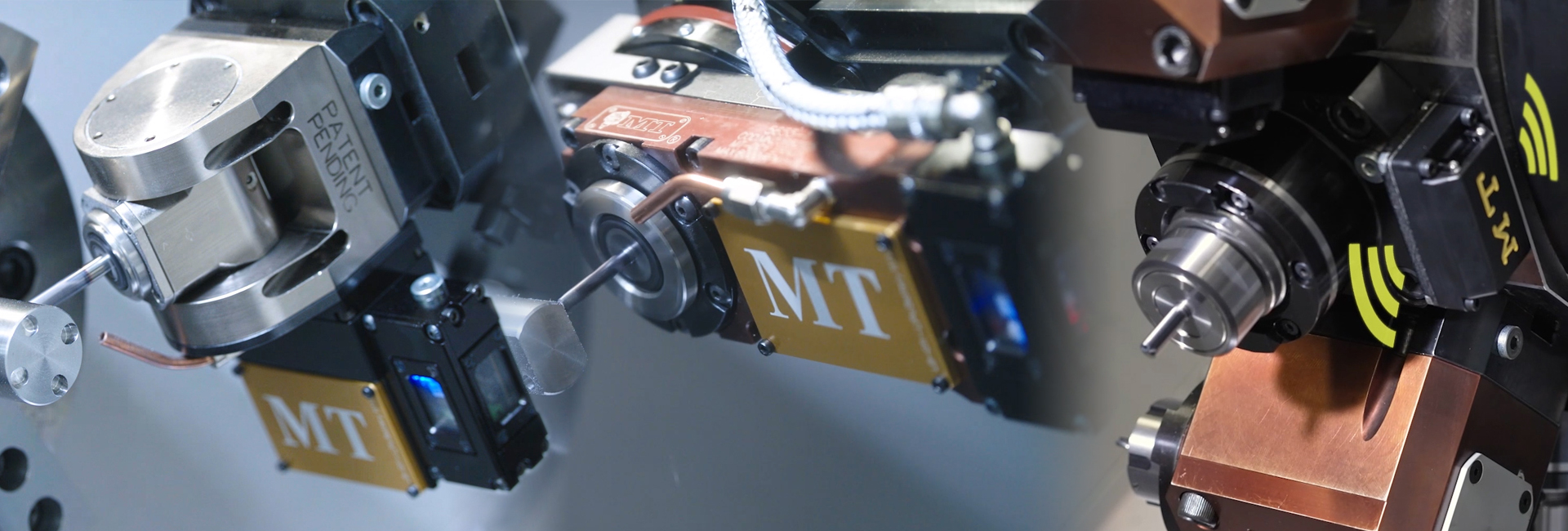

We have developed MT-DCM Digitally Connected Machining technology, which includes solutions that integrate mechanics with electronics and sensors to allow machine tools to perform more complex and reliable machining, where the process is constantly monitored:

- Touch probe protection on lathe: MT-TPS Touch Probe Shield

- Tool break and wear monitoring: MT-SmartForce

- Additional connected Y axis: MT-DCY Digitally Connected Y-Axis

- Connected automatic adjustable angle module: MT-DCB Digitally Connected B-Axis

- Driven tool holder monitoring: MT-SmartLife

Contact us

Product search

Search by code...

Search by catalog MT

Advanced product search

The toolholders make the difference

Find out how M.T. technologies can help you manufacture complex and precise parts minimizing processing times

, then

, then to install our app

to install our app