The range of

MT-DCM Digitally Connected Machining solutions, developed and introduced on the market by MT for the

first time in 2017, opens a new frontier in the world of mechanical machining on turning centers.

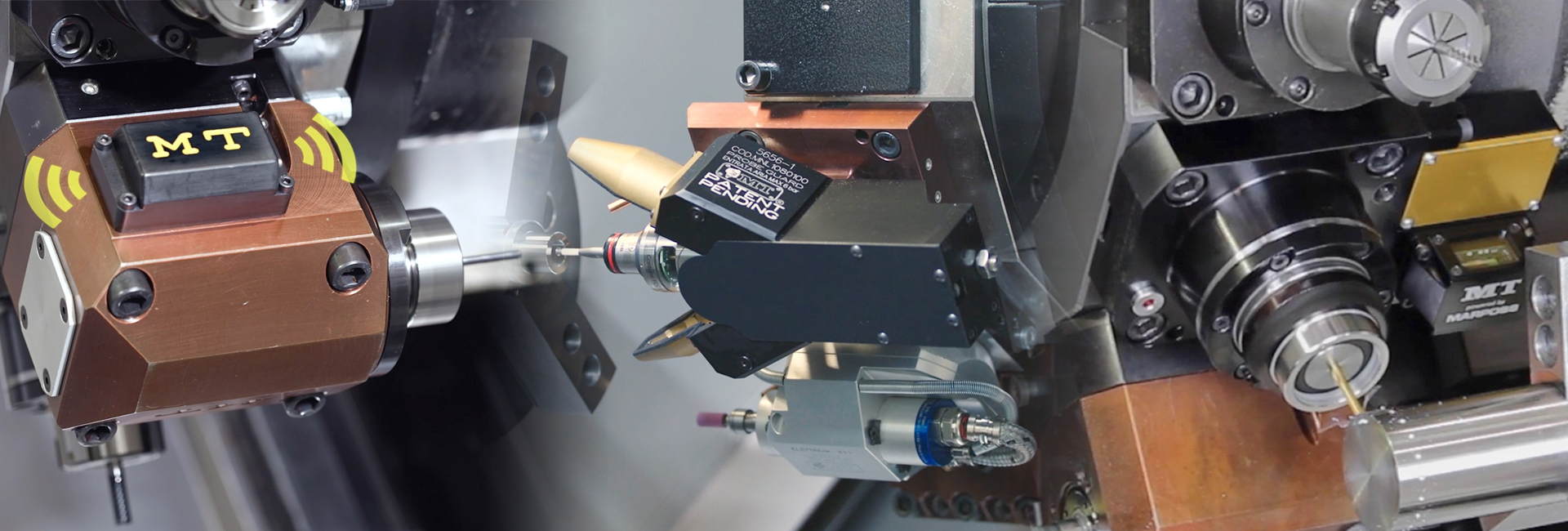

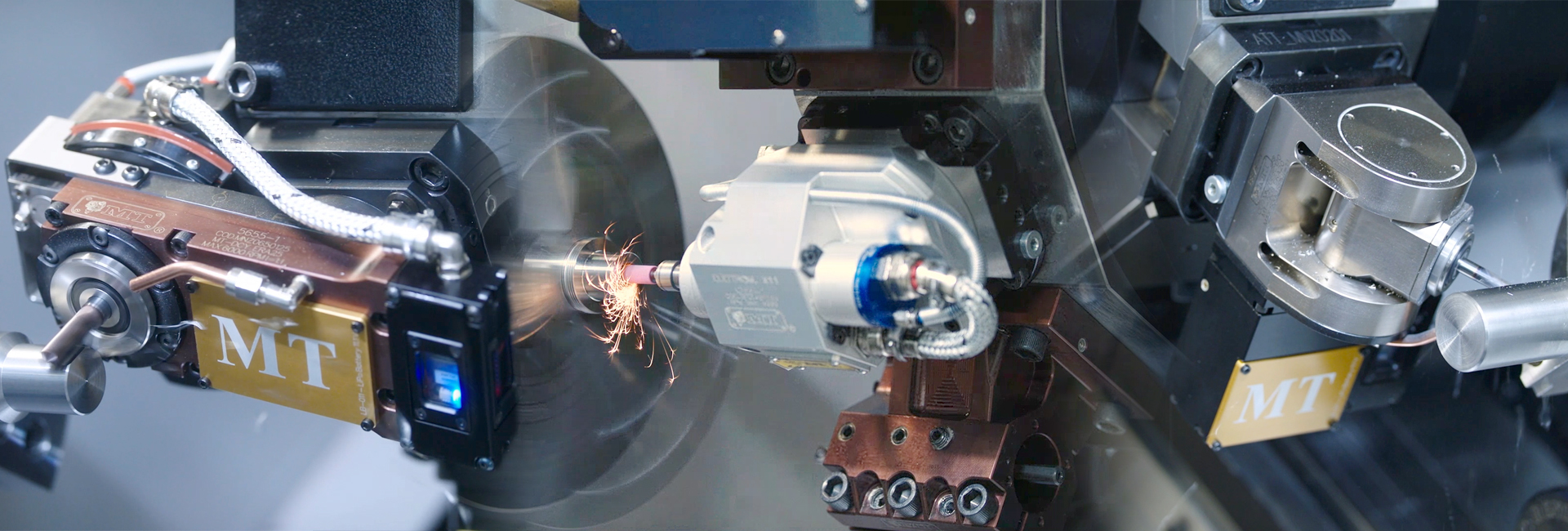

In these products, the mechanic integrates with sensors and electronics to allow machine tools to produce more and more complex workpieces where the process is constantly kept under control.

In highly automated large series production contexts it is essential to control all the phases of the working cycle: from the dimensional control of the workpiece to the tooling management, to the maintenance of the machine components, up to the management of any anomalous events. MT-DCM solutions make this possible on the standard lathe equipped with a driven tool turret.

MT-SmartForce modules, thanks to on-board sensors, integrate with the numerical control of the machine allowing real-time verification of the machining, monitoring the presence, breakage and wear of the tools and detecting any abnormal machining conditions. In case of problems, the processing stops, safeguarding the machine and reducing waste.

MT-TPS Touch Probe Shield allows safe in-process measurement of the workpiece directly on the lathe, protecting the touch probe from damages due to chips, dust and coolant that could occur in the working area of the machine.

MT-SmartLife modules create a new frontier in predictive maintenance on machine tools. Equipped with NB-IoT technology, these driven tool holders communicate directly with the cloud without requiring operator intervention or the presence of external gateways, sending information on their operation that can be viewed through a dashboard from any device.

MT-DCM solutions allow you to extend the functionality of the machine tool!

X11 Powered Electrospindle allows high-speed machining , up to 60,000 rpm, without requiring electrical wiring in the machine, as the energy required for the operation of the electrospindle is generated on board the device.

MT-DCY Digitally Connected Y-Axis allows, even on machines not equipped with a Y axis, to perform off-center drilling, threading and milling. The offset in Y is managed directly by the device, which communicates with the machine via the Bluetooth protocol.

Thanks to the MT-DCB Digitally Connected B-Axisit is possible to make holes and threads with different angles using a single adjustable driven toolholder. Positioning is automatically managed by the device thanks to the installed motor, battery and electronics.

The MT-DCM solutions, many of which have been patented, are the evidence of the innovative attitude that have always distinguished us.

MT: Research and Innovation - Made in Italy

Product search

Search by catalog MT

Advanced product search

If you don't find what you are looking for, contact us!

The toolholders make the difference

Find out how M.T. technologies can help you manufacture complex and precise parts minimizing processing times

, then

, then to install our app

to install our app